Rising Voltage Measurement is Easy - Capacitance Meter

Measure the Rising Voltage

In situations when the capacitor leakage tester is joined with the capacitor, it gets charged up with the existing current value. Our capacitance meter will measure the rate at which the voltage rises inside the capacitor because of the influence of the current. We measured this capacitance as a voltage increment function. You see that the slower the voltage rise in the capacitor, the larger will be its capacitance and it will be easy to understand its value. This capacitance meter supplier product will give you exact data about the voltage so you can provide the appropriate voltage to your freshly built devices.

Call Us +91 727-835-4202

Latest

Related Products

Have a Full Control

Bypass High-Frequency Alternate Current

The product of the top capacitance meter manufacturers, i.e. SB Electrotech’s product will ensure that it also measures the capacitance after bypassing the high frequency of the alternating current. When this current is passed having a high frequency, you will know the resulting voltage change and capacitance as a resulting voltage. Try the capacitance product today to explain the leakage of current in a device, resistivity in an apparatus, and inductance of it. Take it at an affordable price from our site.

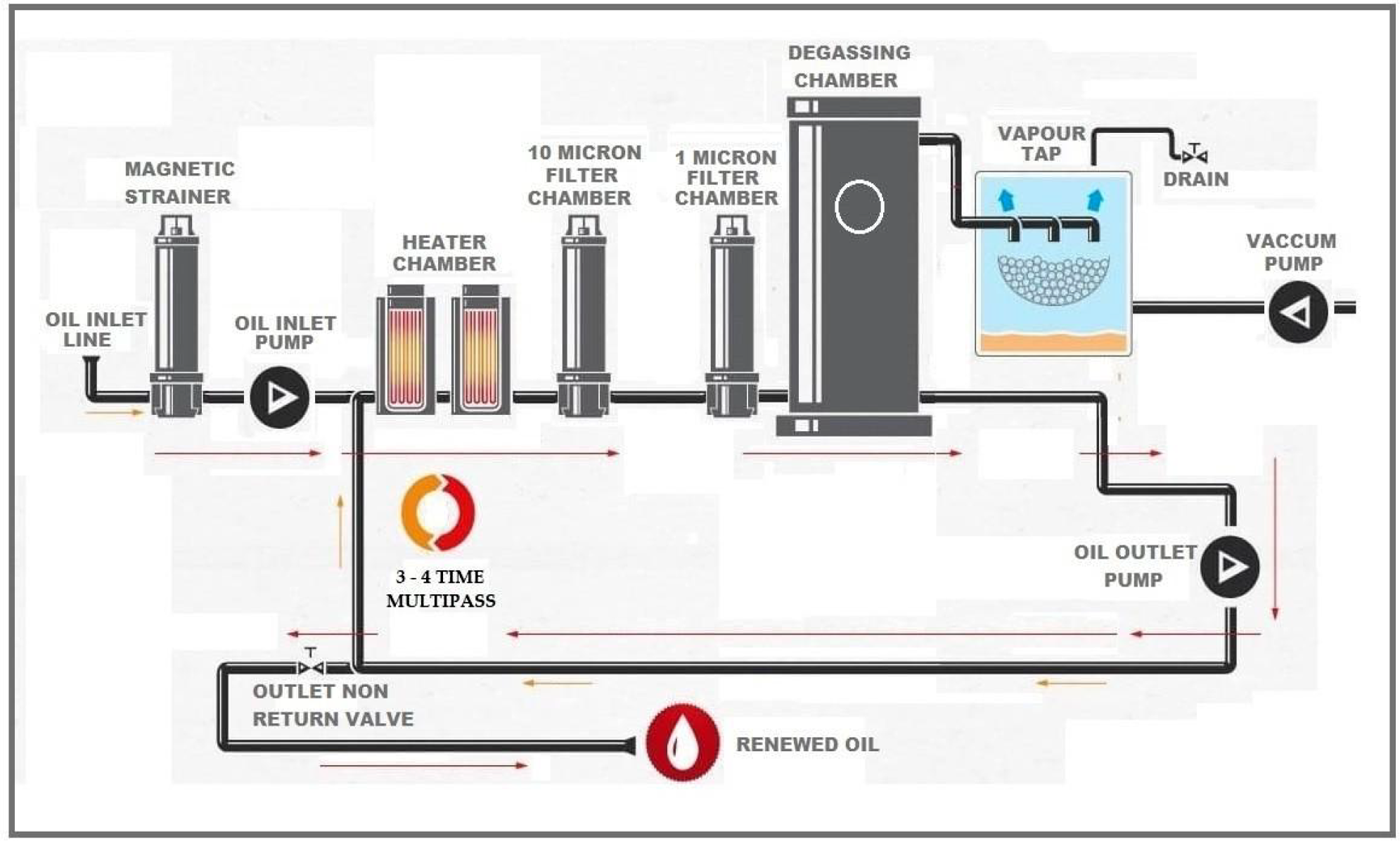

- Imported filter cartridges.

- Available in filter cartridge models.

- Available in Capacity Up-to 600 LPH.

- Major pipe connections are made of wire braided hoses.

- Ball valves with SS balls and Teflon seating.

- Rugged construction, resulting in long years of service.

- Centralised control panel (Fuse less panel using MCCBs, MCBs).

- Powder coated outer panels and internal parts spray painted with PU Paint.

- Temperature gauge, vacuum gauge, compound gauge, Safety relief valves.

- Mounting options like mobile (with Jeep Wheel), semi-mobile (with castor wheel) and skid.

- Improves dielectric strength of the Transformer oil from 25 KV to 65 KV & above In 3 to 4 Passes.

| Parameters | Unit | Value |

| Flow Rate | L/H | 600 |

| Inlet Pump | L/M | 20 |

| Outlet Pump | L/M | 20 |

| Heating Power | KW | 9 |

| Vacuum Pump | L/M | 200 |

| Inlet/Outlet | mm | Φ12 |

| Magnetic Strainer | Micron | 50 |

| Secondary Filter | Micron | 2 No.10µ 2 No. 1µ |

| Operation Temperature | ℃ | 40 ~ 70 (65°C is best) |

| Power Supply | – | 390-450 VAC, 3 Phase, 50 Hz |

| Ambient Temperature | ℃ | -25 ~ 55 |

| Weight | KG | 350 |

| Inlet/Outlet Hose Pipe | Meter | 10 Meter Each. |

| Parameter | Used Oil | After Treatment |

| Moisture(Water Content) | ≥20 ppm | ≤ 5-10 PPM |

| Gas Content | 10% | ≤0.1% (Vol) |

| Particle size (Filtration Level) | 50-100 micron | ≤ 1 micron |

| Breakdown Voltage(Dielectric) | 25 kV | ≥ 65KV |

When this machine start working and vacuum degree is upto the set value, the used oil will be sucked into the primary filter & secondary filter under the pressure difference, the primary filter & secondary filter will remove the big size impurities/ particles, then the oil which just contains the tiny particles is heated by the heaters. Then the heated oil enter into the vacuum separator, through the function of vacuum pressure and degassing system, the moisture content in the oil, which is vapoured & separated from the oil quickly, is either discharged under the process of the vacuum system or refrigerated to liquid water into water receiver, meanwhile de- gasification work is completed. The last procedure is that the fine filter removes the tiny impurities completely. Finally, clean oil goes out through the oil outlet.