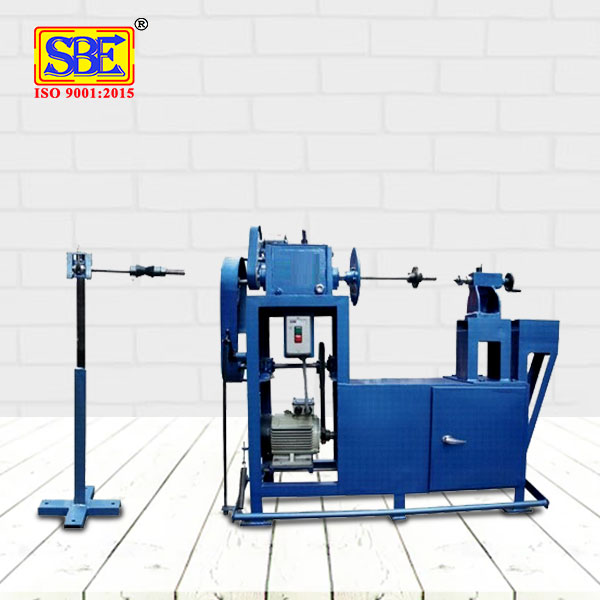

Efficient for the Winding of Coils

The coil winding machines will come in handy for producing the coils. The product can be supreme, its long lasting, and user-friendly. The HV coil winding machine will serve justice for the winding of coils in the motors, chokes, inductors, and transformers. The equipment can be used for wire welding, wire winding, and wire bonding applications. Our transformer HV coil winding machine will produce a coil for the power transformers that helps convert the power voltage from one level to another. Try out the production to grow your repairing or manufacturing unit!

Call Us +91 727-835-4202

Latest

Related Products

Have a Full Control

Eases Up the Circuitry Work

When you use LT Coil winding machine from the leading coil winding machines suppliers in India, you experience that we resolve your electromagnetic coil supply shortage as you can produce it on your own. You can, later on, use it in transformers, generators, and motors for running the electrical operations. Your circuit will be incomplete if you don’t use it and the HV coil winding machine by SB Electrotech, the leading coil winding machines manufacturers in India, will help you make coils to complete the circuitry work. Save your spending on the electromagnetic coils by using this product!

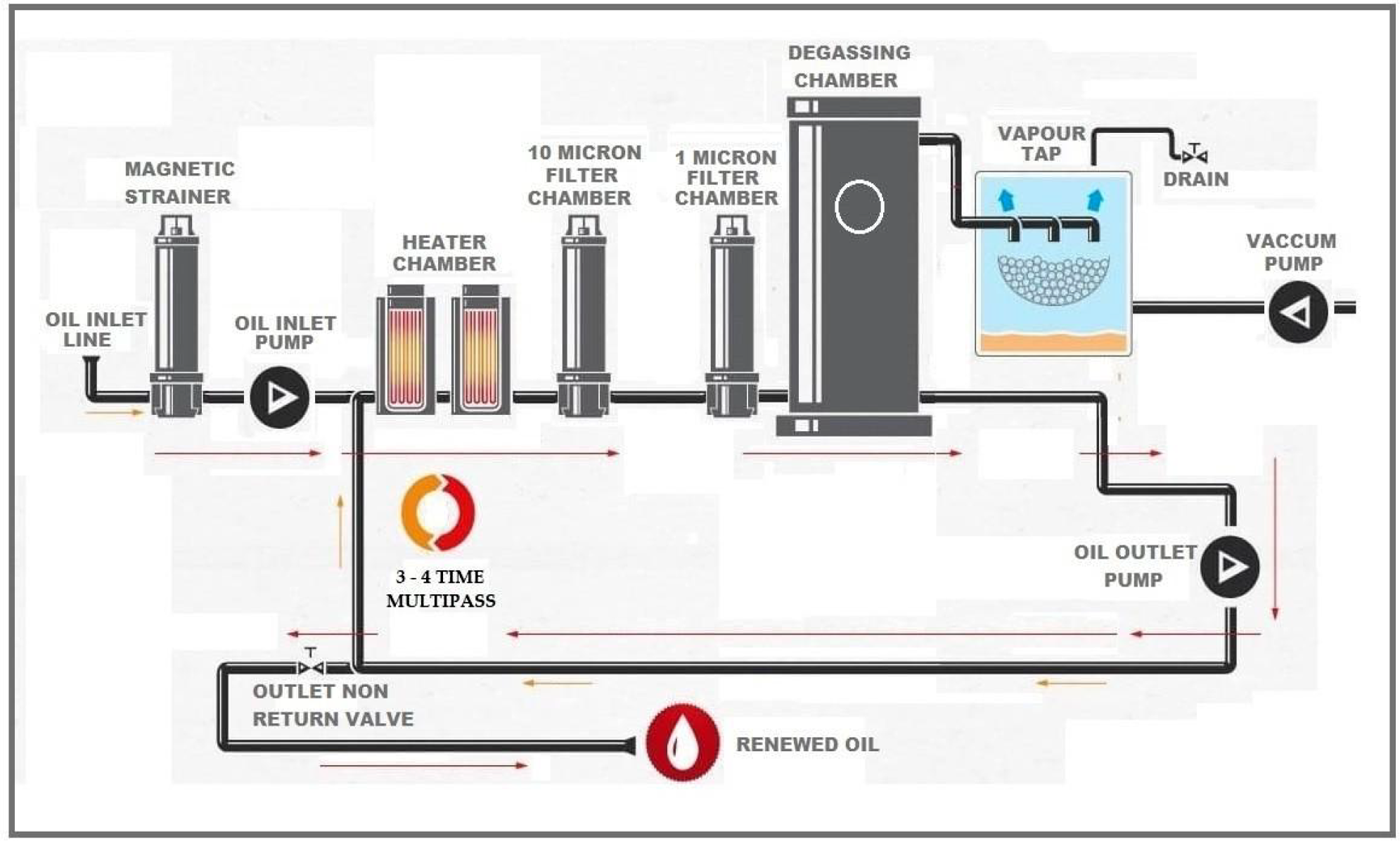

- Available in filter cartridge models.

- Available in Capacity Up-to 600 LPH.

- Mounting options like mobile (with Jeep Wheel), semi-mobile (with castorwheel) and skid.

- Improves dielectric strength of the Transformer oil from 25 KV to 65 KV & above In 3 to 4 Passes.

- Major pipe connections are made of wire braided hoses.

- Ball valves with SS balls and Teflon seating.

- Rugged construction, resulting in long years of service.

- Centralised control panel (Fuse less panel using MCCBs, MCBs).

- Imported filter cartridges.

- Powder coated outer panels and internal parts spray painted with PUPaint.

- Temperature gauge, vacuum gauge, compound gauge, Safety relief valves.

| Parameters | Unit | Value |

| Flow Rate | L/H | 600 |

| Inlet Pump | L/M | 20 |

| OutletPump | L/M | 20 |

| Heating Power | KW | 9 |

| Vacuum Pump | L/M | 200 |

| Inlet/Outlet | mm | Φ12 |

| Magnetic Strainer | Micron | 50 |

| SecondaryFilter | Micron | 2 No.10µ |

| 2 No. 1µ | ||

| Operation Temperature | ℃ | 40 ~ 70 (65°C is best) |

| Power Supply | 390-450 VAC, 3 Phase, 50 Hz | |

| Ambient Temperature | ℃ | -25 ~ 55 |

| Weight | KG | 350 |

| Inlet/OutletHose Pipe | Meter | 10 Meter Each. |

| Parameter | UsedOil | AfterTreatment |

| Moisture(WaterContent) | ≥20 ppm | ≤ 5-10 PPM |

| Gas Content | 10% | ≤0.1% (Vol) |

| Particle size (Filtration Level) | 50-100 micron | ≤ 1 micron |

| BreakdownVoltage(Dielectric) | 25 kV | ≥ 65KV |

When this machine start working and vacuum degree is upto the set value, the used oil will be sucked into the primary filter & secondary filter under the pressure difference, the primary filter & secondary filter will remove the big size impurities/ particles, then the oil which just contains the tiny particles is heated by the heaters. Then the heated oil enter into the vacuum separator, through the function of vacuum pressure and degassing system, the moisture content in the oil, which is vapoured & separated from the oil quickly, is either discharged under the process of the vacuum system or refrigerated to liquid water into water receiver, meanwhile de- gasification work is completed. The last procedure is that the fine filter removes the tiny impurities completely. Finally, clean oil goes out through the oil outlet.