12000 LPH Capacity Based High Transformer Oil Filter Machine

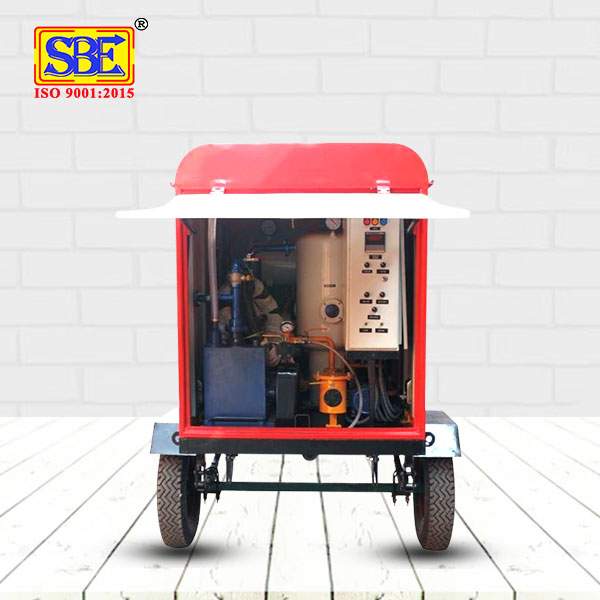

Take the Machine Anywhere on Wheels

We can easily carry away the transformer oil filtration machine to any location where the transformer is equipped already or to a manufacturing unit using its jeep wheels and castor wheels. The tool filters, Vacuum Pumps out the pollutants present in the transformer oil so the contaminates that get entered the machine by climate, dirt, and water get removed easily. The transformer oil filter machine suppliers in India have developed a machine that’s easy to carry and straightforward to use for the filtration of oil used in the transformer.

Download Catalogue

Low Maintenance Operations

The transformer oil filtration process will simply not need any high maintenance during the operation of the machine for a longer duration. The transformer oil filter machine manufacturers in India have given you the Temperature gauge, vacuum gauge, compound gauge, Float Switch, safety relief valves for a sturdy quality. When the product is so easy to maintain and causes low issues in its operations, it’s going to give you better returns for years in your business.

- Imported filter cartridges,

- Available in filter cartridge models.

- Available in capacity Up-to 12000 LPH.

- Major pipe connections are made of wire braided hoses.

- Ball valves with SS balls and Teflon seating.

- Rugged construction, resulting in long years of service,

- Centralized control panel (Fuse less panel using MCCBs, MCBs),

- Powder coated outer panels and internal parts spray painted with PU Paint.

- Temperature gauge, vacuum gauge, compound gauge, Safety relief valves.

- Mounting options like mobile(with Jeep Wheel), semi-mobile (with castor wheel) and skid.

- Improves dielectric strength of the Transformer oil from 25KV to 70 KV& above In 3 to 4 Passes.

| Parameters | Unit | TOFMD 1200 |

TOFMD 1800 |

TOFMD 2400 |

TOFMD 3000 |

TOFMD 4500 |

TOFMD 5000 |

TOFMD 6000 |

TOFMD 12000 |

| Flow Rate | L/H | 1200 | 1800 | 2400 | 3000 | 4500 | 5000 | 6000 | 12000 |

| Inlet Pump | L/M | 20 | 30 | 40 | 50 | 80 | 80 | 100 | 200 |

| Outlet Pump | L/M | 20 | 30 | 40 | 50 | 80 | 80 | 100 | 200 |

| Heating Power | KW | 12 | 30 | 48 | 72 | 96 | 108 | 120 | 144 |

| Vacuum Pump 1st Stage |

L/M | 300 | 400 | 600 | 600 | 800 | 1000 | 1200 | 2000 |

| Booster Pump 2nd Stage |

m³/Hr | – | – | 100 | 200 | 250 | 300 | 400 | 600 |

| Inlet/Outlet | mm | Φ19 | Φ19 | Φ25 | φ25 | Φ38 | Φ50 | Φ50 | Φ62 |

| Magnetic Strainer |

Micron | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Secondary Filter |

Micron | 3 No.10µ 3 No. 1µ |

3 No.10µ 3 No. 1µ |

4 No.10µ 4 No. 1µ |

4 No.10µ 4 No. 1µ |

6 No.10µ 6 No. 1µ |

7 No.10µ 7 No. 1µ |

8 No.10µ 8 No. |

1µ 10 No.10µ |

| Back Filter | – | – | – | 1 No. | 1 No. | 1 No. | 1 No. | 1 No. | 1 No. |

| Operation Temperature |

°C | 40 ~ 70 (65°C is Best) | – | ||||||

| Power Supply | – | 390-450 VAC, 3 Phase, 50 Hz | – | ||||||

| Ambient Temperature |

– | -25 ~ 55 | – | ||||||

| Weight | Kg | 500 | 700 | 900 | 1000 | 1200 | 1300 | 1400 | 2000 |

| Inlet/Outlet Hose Pipe |

Mtr | 10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

10 Mtr Each |

| Parameter | Used Oil | After Treatment |

| Moisture (Water Content) | ≥20 ppm | ≤ 5 PPM |

| Gas Content | 10% | ≤0.1% (Vol) |

| Particle size (Filtration Level) | 50-100 ppm | ≤ 1 micron |

| Breakdown Voltage (Dielectric) | 25 kV | ≥70 KV |

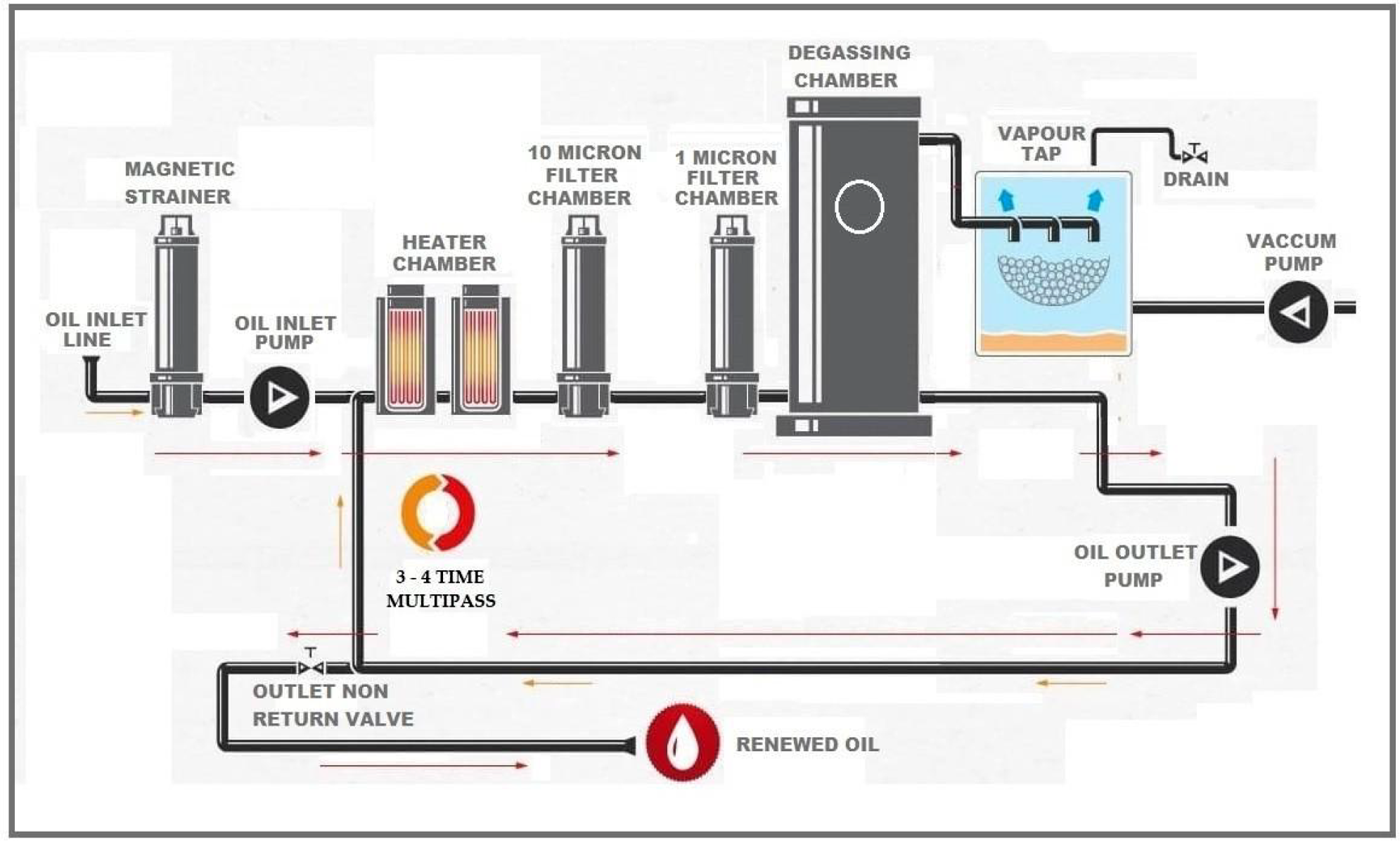

When this machine start working and vacuum degree is up to the set value, the used oil will be sucked into the primary filter & secondary filter under the pressure difference, the primary filter & secondary filter will remove the big size impurities/ particles, then the oil which just contains the tiny particles is heated by the heaters. Then the heated oil enter into the vacuum separator, through the function of vacuum pressure and degassing system, the moisture content in the oil, which is vapoured & separated from the oil quickly, is either discharged under the process of the vacuum system or refrigerated to liquid water into water receiver, meanwhile de- gasification work is completed. The last procedure is that the fine filter removes the tiny impurities completely. Finally, clean oil goes out through the oil outlet.